A borescope is an essential tool for precise inspections and troubleshooting in industrial settings. Often called a pipe inspection borescope in plumbing or HVAC applications—or simply an inspection borescope in broader contexts—these devices let users see into areas that would otherwise be inaccessible. This makes them indispensable in both manufacturing and maintenance work.

In this guide, we cover the definition, applications, benefits, features, and safety considerations of industrial borescopes.

What Is an Industrial Borescope?

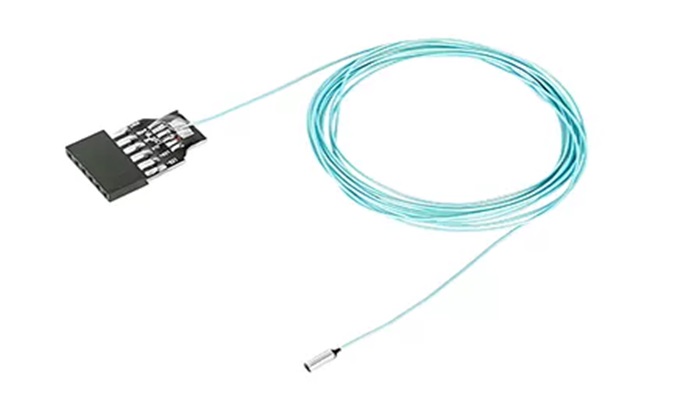

An industrial borescope is designed to provide visual access to hard-to-reach areas in industrial environments. With their slim, flexible probes, borescopes combine high-resolution cameras, LED lighting, and real-time displays to give operators a clear view inside confined spaces.

The technology is similar to flexible medical endoscopes, allowing users to check engines, pipelines, turbines, and other equipment without disassembly.

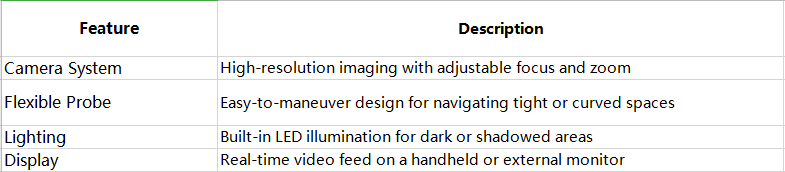

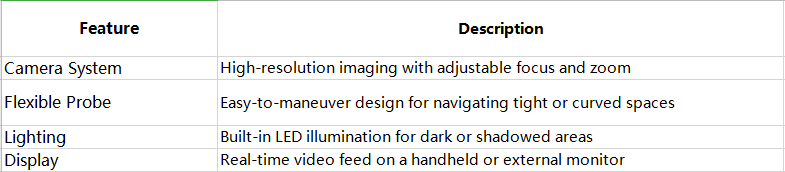

Core Features of Industrial Borescopes

Because of their versatility, borescopes are often marketed as industrial inspection borescopes, reflecting their use in many sectors for quick checks and quality control—without the need for costly equipment teardown.

Common Industrial Applications

The ability to perform non-destructive inspections makes borescopes invaluable across multiple industries:

| Industry | Application |

| Automotive | Internal inspection of engines, transmissions, and other components |

| Aerospace | Examination of turbine blades and structural integrity |

| HVAC | Inspection of ductwork, cooling systems, and air handling units |

| Plumbing | Visual assessment of internal pipe conditions and blockages |

In manufacturing, pipe inspection borescopes help engineers spot defects or wear early, improving quality control and reducing downtime.

Benefits for Maintenance and Repair

Using an industrial borescope for maintenance offers major advantages:

Preventive Maintenance: Spot issues like wear, corrosion, or blockages early to extend equipment lifespan.

Reduced Downtime: Non-invasive inspections mean quicker checks without stopping operations.

Improved Safety: Remote visualization cuts down on hazardous manual inspections.

These benefits make borescopes a cost-effective and reliable inspection tool for any maintenance team.

Key Features to Consider When Buying

When selecting an industrial borescope, keep these factors in mind:

| Feature | Importance |

| Image Quality | Clear visuals are critical for accurate diagnostics |

| Probe Length & Material | Determines reach, flexibility, and durability in harsh environments |

| Connectivity | Supports data transfer, storage, or remote viewing |

| Water & Dust Resistance | Ensures reliable use in rugged or wet conditions |

Choosing the right borescope ensures efficiency in both routine inspections and specialized tasks.

Safety Considerations in Use

While borescopes simplify inspections, safe use is essential:

Electrical Safety: Avoid risks when working near conductive fluids or energized equipment.

Mechanical Safety: Operators should be trained to handle probes safely to avoid equipment damage.

Ergonomics: Lightweight, comfortable designs reduce fatigue during long inspections.

By following these practices, teams can maximize both safety and equipment life.

Conclusion

Industrial borescopes—also called pipe inspection borescopes or inspection cameras—provide unmatched advantages for inspecting, diagnosing, and maintaining complex machinery. With high-resolution imaging and flexible design, they improve efficiency, safety, and quality assurance across industries including automotive, aerospace, HVAC, and plumbing.

References: