How Pipeline Endoscope Revolutionizes Industrial Inspection Processes

Modern industrial pipeline inspection faces challenges such as limited visibility and complex operations. The handheld Pipeline Endoscope achieves technological breakthroughs through three core advantages:

High-Definition Imaging System

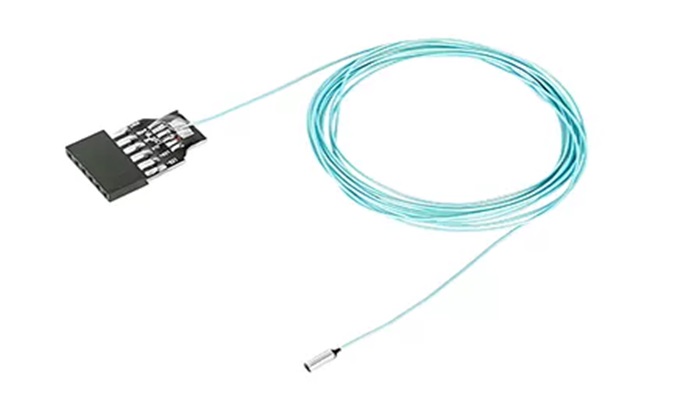

120° wide-angle lens paired with a 500,000-pixel CMOS sensor

6mm ultra-thin probe capable of accessing DN25 and larger pipelines

0.01mm measurement accuracy compliant with ASME B31.3 standards

Intelligent Operation Experience

5-inch IPS touchscreen for real-time inspection display

WiFi/HDMI dual-mode video output

Automatic defect annotation and measurement report generation

Full-Scenario Adaptability

IP67 protection rating suitable for humid and dusty environments

Operating temperature range of -20℃ to 60℃

Equipped with magnetic retrieval tool and side-view lens as standard

"In petrochemical pipeline inspections, our handheld pipeline endoscope reduced single inspection time from 3 hours to 40 minutes," said a chief of equipment at a special inspection institute.

Precision Meets Innovation: The Future of Industrial Inspection

With cutting-edge advancements in imaging and data analysis, modern industrial endoscopy has evolved from basic visual inspections to comprehensive intelligent diagnostic solutions:

Smart Inspection Technology

Automated Defect Recognition – AI-driven algorithms accurately identify common industrial flaws (cracks, corrosion, weld defects)

Quantitative Measurement System – Precise dimensional analysis of detected anomalies with ±0.05mm accuracy

Instant Severity Assessment – Color-coded alerts prioritize urgent repairs (Green/Yellow/Red classification system)

Cross-Industry Applications: Real-World Cases of Pipeline Endoscope

Chemical Industry

Energy Infrastructure

Technical Comparison Table

| Item | Traditional Methods | MAIYIS PE Series |

| Inspection Depth | ≤5m | 20m fiber optic extension |

| Resolution | 720P | 1080P + laser ranging |

| Data Retention | Manual recording | Cloud-based automatic archiving |