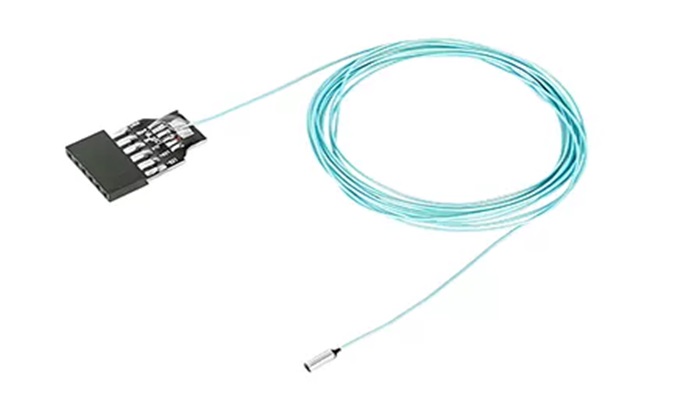

Uses of Industrial Maintenance Borescope

Troubleshooting:

Inspect the inside of equipment (e.g., engines, pipes, turbines, etc.) for wear, corrosion, cracks, or foreign objects.

Locate leaks or blockages.

Quality Control:

Check for weld quality, assembly accuracy or surface defects during the manufacturing process.

Preventive Maintenance:

Regularly check the condition of equipment to detect potential problems in advance and avoid downtime.

Safety Inspection:

Reduce safety risks by replacing manual inspections in hazardous environments such as hot, toxic or confined spaces.